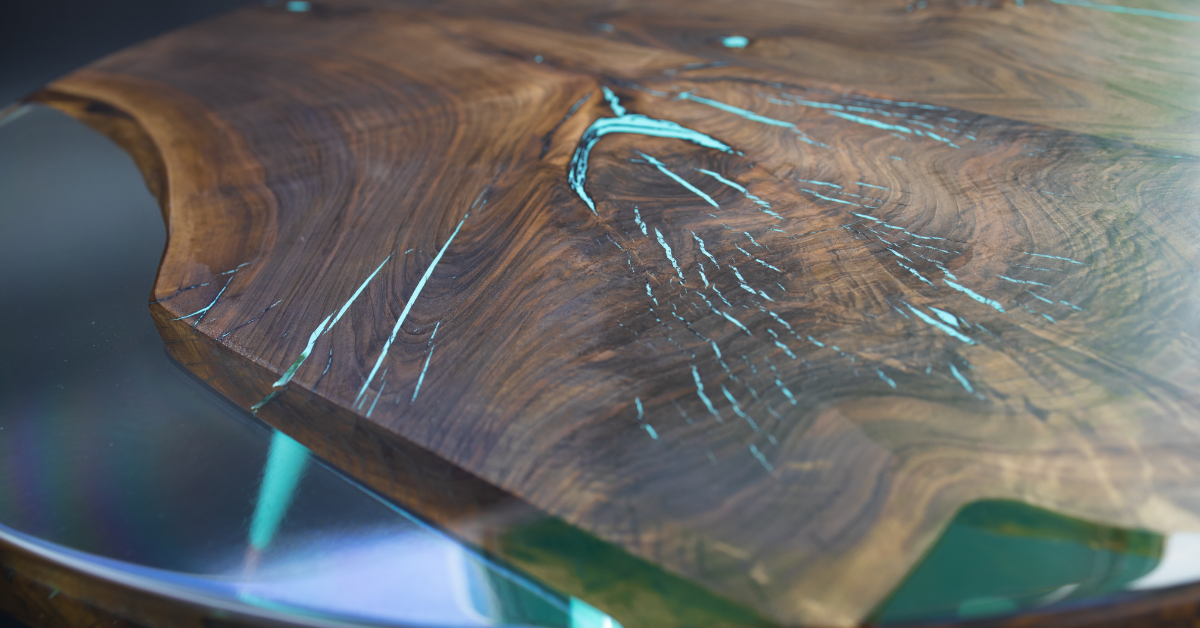

Epoxy resin is a uniquely versatile substance. From filling gaps to repairing cracks, protecting surfaces against wear and tear, and bonding two materials together, it can be used for an exceptionally wide range of purposes. Known for its exceptional durability, epoxy has residential, commercial, as well as industrial applications.

What Exactly Is an Epoxy Resin and How Does It Work?

The term ‘epoxy’ refers to a class of polymer and prepolymer compounds containing epoxide groups. It is formed by combining two substances – resin and hardener.

When combined, the epoxy groups in the resin get interlinked with the chemical units of the hardener – resulting in an extremely strong bond. Apart from this, the resin also contains hydroxyl groups, which have the capacity to bond with other materials. When applied on a surface, the hydroxyl groups in the resin tend to bond with the chemical units of the material and form a virtually indestructible bond.

Epoxy Resin Curing Process

When applied or poured onto a surface, epoxy resin tends to undergo a process called curing – during which it forms an extremely hard layer over the surface upon which it is applied.

Curing is an exothermic reaction, which releases heat into the surface. The reaction can happen only when there is sufficient heat in the atmosphere. This is why it is advised that epoxy resins must be used for coating surfaces – or for any purpose for that matter – only at a temperature of 75ºF or higher.

If the temperature dips below 75ºF, the heat released during the exothermic reaction (the curing process) might get trapped inside and result in an incomplete polymerization. As a result, the epoxy layer or coating might not be fully cured and therefore might not be as hard and durable as expected.

Curing Time for Epoxy Resins

The time needed for curing depends on the type of epoxy resin you use. If it is a clear epoxy resin (commonly known as a tabletop epoxy resin), it can take up to 72 hours to become hard enough to be used.

In the case of a deep pour epoxy resin, the curing time could be much longer. It can take up to 14 days for the epoxy to cure, depending on the depth of the pour and the temperature applied.

UltraClear Epoxy – The Right Choice for All Your Epoxy Resin Needs

UltraClear Epoxy offers exceptionally high-quality, commercial-grade table top epoxy resins as well as casting resins, which are known for their durability. Scratch, stain, and heat resistant, our epoxy resins are ideally suited for residential as well as commercial uses.

With a Shore D Hardness Rating of 98, UltraClear Epoxy is by far the hardest, most durable epoxy available on the market today. We also offer a wide array of pigments, dyes, and supplies needed for your epoxy projects. All our products are made in America and are free of volatile organic compounds.

If you have questions about UltraClear Epoxy or wish to place an order, call us today at 800-259-1619 or simply fill out this online contact form.