An epoxy coating is the best way to protect your bar top against spills, stains, and scratches while also increasing its lifespan. The hard, non-porous surface of the epoxy coating can also prevent your bar top from absorbing moisture and harboring bacteria.

If this is the first time you are working with epoxy, you might be worried about whether you can get everything right. Fortunately, the pros at UltraClear Epoxy have you covered!

Below, we'll discuss four proven tips that can help you get everything right for your bar top epoxy coating.

Four Proven Tips for A Perfect Epoxy Coating |

|

1. Choose the Right Epoxy Resin. |

Choose the Right Epoxy Resin

The outcome of your bar top epoxy coating project largely depends on the quality of the epoxy resin you choose. The higher the quality, the better the results will be.

Ideally, you should choose a commercial grade bar top epoxy which meets the following criteria.

- Has a Shore D hardness rating of 90 or above

- Made of non-fade pre-polymers

- Can give a high-gloss finish

- Free of volatile organic compounds

- Scratch and crack resistant

- Does not yellow or fade

You can use this calculator to determine how much epoxy resin you need for your project.

Check the Room Temperature and Humidity

Before you start working, check the room temperature and make sure it is 75ºF or above. If it cures significantly below 75ºF, the heat released by the epoxy resin during the curing process might get trapped inside, resulting in a dull, cloudy-looking bar top epoxy coating.

Incorrect environmental temperature can also cause an excess formation of bubbles, so use heaters if needed and make sure the room temperature does not dip below 75ºF.

Furthermore, the humidity of the epoxy environment should be kept below 60% until it's mostly cured (about 72 hours of curing, generally). This will prevent moisture from building within the resin finish, which can otherwise mar its final appearance with cloudy patches.

For a better understanding of epoxy drying times, check out our guide to curing.

Prep the Surface

Before applying any epoxy, wipe the surface with a clean cloth. If the bar top has a beer tap, make sure you turn it off at least a couple of hours before you start applying the epoxy. If the tap is too cold, the bar top epoxy coating will not cure and set the way it should.

Cover the floor with plastic sheeting to make sure the epoxy resin does not make a mess. Mix the resin and the hardener in the right ratio – as per the manufacturer’s instructions. Mixing them in the wrong ratio can not only make it harder for you to apply the epoxy but also affect the performance and durability of the bar top epoxy coating.

Apply the Seal Coat and Flood Coat

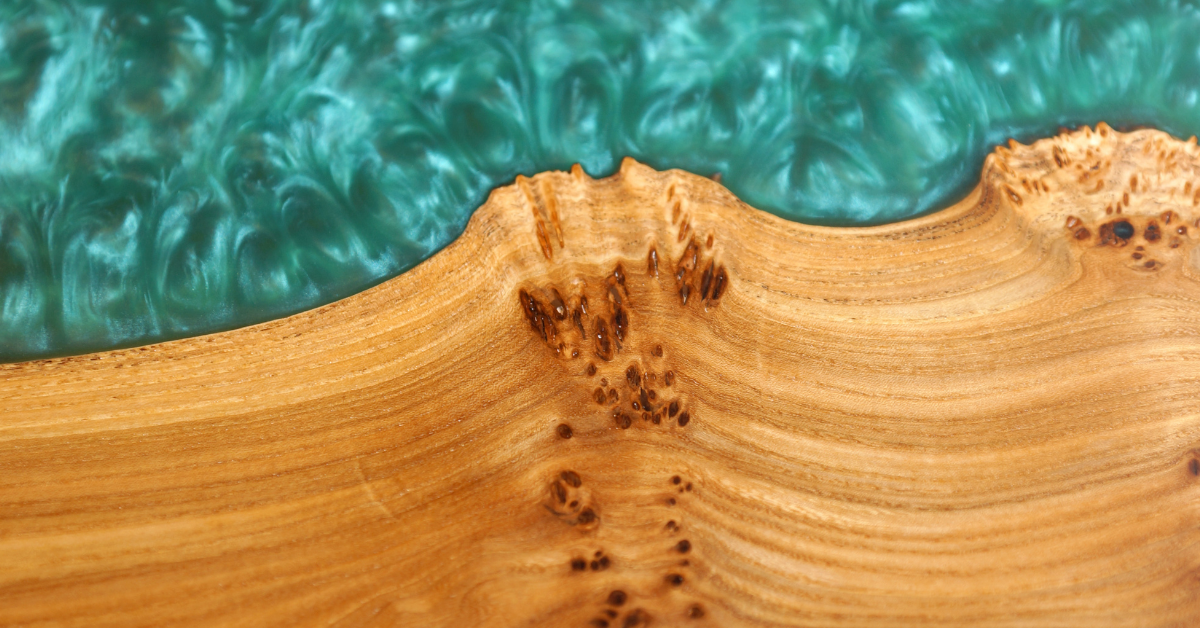

Epoxy finishing typically involves two different coatings: the seal coat and the flood coat.

The seal coat is a thin coat that gets manually applied with a brush. It fills in any pores in the bar surface and readies it for the flood coat by removing air that would otherwise become bubbles. The flood coat, on the other hand, is the proper pour. It's what becomes the smooth, final surface after a curing period.

For a perfect epoxy finish:

- First apply the seal coat in a thin, even layer using a paint brush.

- Four to six hours after applying the seal coat, you can pour the flood coat.

- Then, if you notice any air bubbles on the surface, pop them using a heat gun.

- Once you're done, let the epoxy cure for at least 72 hours.

UltraClear Epoxy: The Right Choice for the Perfect Bar Top Epoxy Coating

UltraClear Epoxy offers the most advanced commercial-grade epoxy resin for your bar top. With a Shore Hardness rating of 98, our epoxy is designed to last long and protect your bar top against stains and scratches for years to come. And thanks to our epoxy’s crystal clear finish, your bar top will look more appealing than ever before.

To find out more about bar top epoxy coating or to place an order for UltraClear Epoxy, call us today at 800-259-1619 or reach us online.