Among epoxy variants, table top epoxy and deep pour epoxy are perhaps the most common, especially for DIY projects and commercial bar tops and table tops. These two types of epoxy intended for similar purposes, and in turn there is significant overlap in what they can be used for.

When choosing an epoxy for a project, there are several factors to consider, with hardness being one of them. In this article, we'll talk about the difference in hardness between table top epoxy and deep pour epoxy. We'll also discuss other key differences between the two epoxy types that become apparent throughout the application process, and why they need to be handled slightly differently as a result.

Is table top epoxy harder than deep pour epoxy?

Although table top epoxy and deep pour epoxy are similar in function once cured, there's a noteworthy difference in how hard they are. Table top epoxy tends to be much strongest than deep pour epoxy of the same quality.

Epoxies like these come as two separate components, resin and hardener. When these components are combined, a hardening reaction occurs, and the epoxy gradually transitions from a liquid to a very sturdy solid. This process is called "curing".

Learn more about the curing phase here!

Once fully cured, epoxy becomes usable as a solid surface for normal interaction. However, because of its high resilience and smooth exterior, it's often considered a superior material choice for use in high-traffic environments or in places where dirtiness is a concern, as epoxy surfaces are also easy to clean.

Table top epoxy is stronger than deep pour epoxy

When it comes to sheer strength, table top epoxy will outdo deep pour epoxy in every metric. For instance, in our store we offer both our UltraClear Deep Pour Epoxy and our UltraClear Bar & Table Top Epoxy, and while our Deep Pour Epoxy holds its own in most regards, it's our Table Top Epoxy that truly excels in resilience. In fact, on the Shore hardness test, we rated an extremely high 98 out of 100.

What is a Shore hardness rating?

The Shore hardness test uses a tool called a durometer to test hardness by attempting to place a dent in a material. The tools come in different forms and are used to apply high pressure to a material for 15 seconds, at which point the depth of any indentation made is checked. The less of a dent it makes, the higher the hardness rating the material achieves, on a scale of 0 to 100.

In other words, for the strongest possible epoxy finish, go with our UltraClear Bar & Table Top Epoxy. However, hardness is rarely the only meaningful factor in choosing an epoxy product. In the next section, we'll discuss other aspects worth considering.

Other differences between table top and deep pour epoxies

In addition to the disparity in hardness between table top epoxy and deep pour epoxy, there are also other differences. These include:

- Mixing Ratios—The amount of each component needed for an epoxy to achieve a perfect blend.

- Viscosity—The epoxy's resistance to movement, aka the flow of the epoxy in liquid form.

- Viable layer depth—How thick a layer of that epoxy type can be before there's a substantial risk of imperfection in the final cure.

- Cost—Deep pour epoxy tends to be more expensive for several reasons, primarily related to production.

Let's take a look at each of these aspects.

Difference #1: Epoxy mixing ratios

The vast majority of epoxy products use a two-part system to initiate curing. These epoxies are produced as two separate components that need to be combined in a specific ratio to induce the curing process which generates the beautiful, transparent material epoxy is known as.

For most table top epoxy resins, this mixing ratio is 1:1. This means equal amounts of resin component and hardener component should be mixed together to get a clean epoxy blend.

On the other hand, for deep pour epoxy, the ratio tends to favor the resin component, with ratios such as 2:1, 3:1, or greater. Our UltraClear Deep Pour Epoxy, for example, using a 2:1 ratio of resin to hardener.

Because of this variation between different types of epoxy, always make sure you know the correct mixing ratio for your chosen product.

Learn more about measuring out epoxy components here!

Difference #2: The viscosity of different resins

Another relevant disparity between epoxy types is their viscosity. Every epoxy has a distinct level of viscosity, which influences the way it moves once applied, as well as how well it spreads on or clings to a surface (especially at an angle) while it hardens.

For most table top epoxy products, viscosity levels will be high. These products are formulated to cure dense and strong, and high viscosity is a side effect of that. Additionally, it's table top epoxy that is generally used for applying epoxy seal coats. The result of this high viscosity is that the epoxy won't flow as smoothly or quickly, nor will it spread quite as thin as light epoxies.

In contrast, deep pour epoxy tend to have much lower viscosity ratings, bordering on watery. Deep pour epoxy is formulated to fill in spaces with thick layers of epoxy, and one consequence of this is the low-viscosity level it features. This makes it unsuitable for epoxy seal coats, but allows users to perform much larger, deeper epoxy pours as needed.

Difference #3: The epoxy's maximum viable layer depth

Some epoxy resins can only be poured in thin coatings, while others are viable for extra-thick layers. Epoxies like our UltraClear Bar & Table Top Epoxy are meant for thinner pours. They're naturally self-leveling and will spread out to the appropriate layer thickness, assuming no interference. For most table top epoxies, this self-leveling thickness is between 1/16 of an inch and 1/8 of an inch.

Achieving a thicker finish with table top epoxy

When a thicker finish is needed, users have a few different options. The first is to apply multiple layers of the table top epoxy. This can take extra time but is perfectly feasible otherwise, requiring a partial cure (and occasionally a light sanding) before each subsequent coating.

Some users elect to ignore the warnings for layer thickness and apply overly thick layers of table top epoxy. While this is technically possible, there's a much greater risk of imperfections such as air bubbles, clouding, or tackiness in the resulting finish.

For the best in quality, try our UltraClear Bar & Table Top Epoxy, located here.

Deep pour epoxy allows for much greater depth

Alternatively, there's a much more convenient way, which is to use a deep pour epoxy to reach the desired depth. Deep pour epoxy doesn't self-level like table top epoxy. Instead it flows like water and fills in any space—be it a mold, a gap within a substrate, or something else—in thick layers of up to 2 inches.

Get strength, beauty, and depth all at once with UltraClear Deep Pour Epoxy, found in our store!

Difference #4: Epoxy types vary by cost

The cost of epoxy differs between table top epoxy and deep pour epoxy vary. While this difference is apparent by quality and brand, it's also determined by type, with deep pour epoxy of any brand being more expensive than its table top epoxy counterpart(s). There are two primary reasons for this:

-

Specialized Formulation: Deep pour epoxy is formulated to have a lower viscosity, which allows it to flow more easily into molds and crevices, filling spaces without trapping air and forming bubbles. This specialized formulation often requires different or additional raw materials that can increase the cost.

- Thicker Applications: Deep pour epoxy is designed to be applied in much thicker layers without cracking or overheating during the curing process. The chemical additives that prevent these issues add to the complexity and cost of the product.

When choosing a deep pour epoxy, it's best to aim for high quality. While a low-cost epoxy may seem more appealing up front, most users find that the risk of resin cure failure or subpar quality is not worth the reward in potential savings.

Additional Resources

Here are some additional resources you may find useful:

- The 4 biggest mistakes people make when measuring epoxy

- 5 common slip-ups to avoid when mixing epoxy resin

- 5 tricks to achieve a perfect epoxy cure

UltraClear Epoxy: Resin Products of Unmatched Quality

As with any material, epoxy resin has both pros and cons. But no other sealant has so few weaknesses, and that's what puts epoxy above all other options when it comes to being a finish for high-traffic fixtures and furniture such as countertops, table tops, and bar tops. And among epoxy resin products, there are none that match the quality of UltraClear.

You can find our UltraClear Epoxy products on the following pages:

- UltraClear Bar & Table Top Epoxy: The classic choice for bar tops, countertops, and table tops. Rock-solid, waterproof, and crystal-clear.

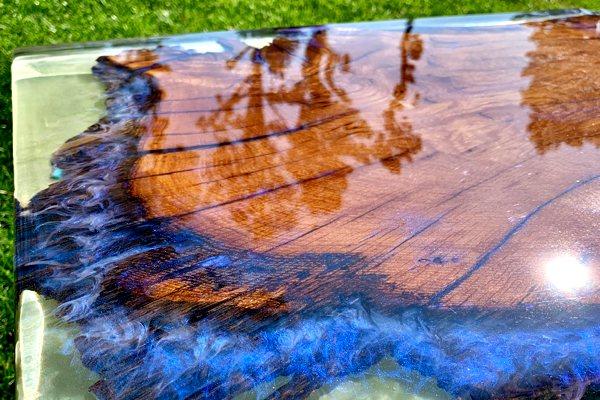

- UltraClear Deep Pour Epoxy: Our deep pour casting resin. Ideal for thick layers, such as those needed for river tables.

- UltraClear Art & Craft Epoxy: Our arts and crafts resin, designed for smaller artistic endeavors which typically involve resin molds and require a bit more fluidity than bar top epoxy.

With high chemical and physical resistance, UltraClear resins can withstand and endure many forms of wear and tear without breaking a sweat or showcasing any cosmetic damage.

Plus, in addition to its ease of application, they also require little upkeep to maintain its pristine appearance. With a high-quality epoxy finish, you can expect a minimum lifespan of 7 years, with no need for reapplication. Beyond that, it's a breeze to renew that coating, requiring only a light sanding and a fresh layer of epoxy.