Among the epoxy types designed for use as a sealant as well as for arts and crafts, table top epoxy ranks highest in durability while also exhibiting a pristine transparent finish.

Because our UltraClear Table Top Epoxy is so strong, it's often the choice users make for projects meant to last a very long time, such as fixtures like bar tops and countertops, as well as furniture including dining tables, end tables, coffee tables, and trays.

But achieving such incredible resilience with table top epoxy does come with a small compromise, and that's what we'll cover below.

In this article, we'll address a common question we get: "How thick can you pour table top epoxy?"

How thick can you pour table top epoxy?

A strong, high-quality table top epoxy can be poured in individual layers of up to 1/8 of an inch. Table top epoxy can be applied in multiple layers, however, meaning the combined total can be much thicker.

Table top epoxy is inherently self-leveling. This means when applied to a flat surface, it will spread out—if there's room—until the thickness of the entire layer is the same. In the case of our UltraClear Table Top Epoxy, that self-leveling thickness is 1/8 of an inch. Note that for other epoxies, it may be less, such as 1/16 of an inch.

Why is there a limit to how thick an epoxy layer can be?

The reason that epoxy layers are limited by thickness is because they're very viscous. When epoxy is applied to a substrate or poured into a mold, it seeps into any pores within the substrate, and these pores contain air. Similarly, with molds, the epoxy may catch air as it fills the mold.

Air within epoxy will try to escape by surfacing. However, table top epoxy is highly viscous, meaning it's thicker and flows less smoothly. When air tries to escape this type of epoxy, it can get stuck partway through if the layer is too thick. Thus, it's important to avoid overly thick layers to prevent air from becoming trapped in the epoxy before it cures, otherwise it remains as a blemish caledl "air bubbles".

Can you prevent air bubbles from occurring?

Though you can't prevent air bubbles entirely, the formation of air bubbles can be greatly mitigated. Air bubbles that form after pouring an epoxy coating can be easily removed with a heat gun or blowtorch.

Here are the steps to accomplish this:

- Ready the device you intend to use, either a heat gun or torch. You'll be keeping the heat source about several inches away from the epoxy coating.

- Activate the tool and move it smoothly over the epoxy layer without linger for more than second over any spot. You'll do a single pass over the entire finish.

- Take a closer look at the epoxy finish to see if any bubbles remain. If any remain, repeat the process by doing another pass.

The reason this works is because the heat generated by the heat gun or torch excites the air in the bubbles, causing them to rise and burst, which then allows the epoxy to settle into its iconic crystal-clear finish.

Can table top epoxy be used for deep pours?

Not exactly. Deep pour epoxies are specially designed for very thick layers. In fact, our UltraClear Deep Pour Epoxy can be poured in 2-inch thick layers, much thicker than table top epoxy, all thanks to a lower viscosity rating which allows air to escape far more easily.

With that said, it is possible to apply multiple layers of table top epoxy consecutively to create a larger combined thickness, equal to a deep pour. Unfortunately, this process takes a lot longer than performing a single deep pour, as each layer must be given time to partially cure before pouring additional layers.

However, you can add a coating of table top epoxy over a deep pour coat.

Both deep pour epoxy and table top epoxy are both great on their own, but for thick layer projects, they truly shine when paired with each other.

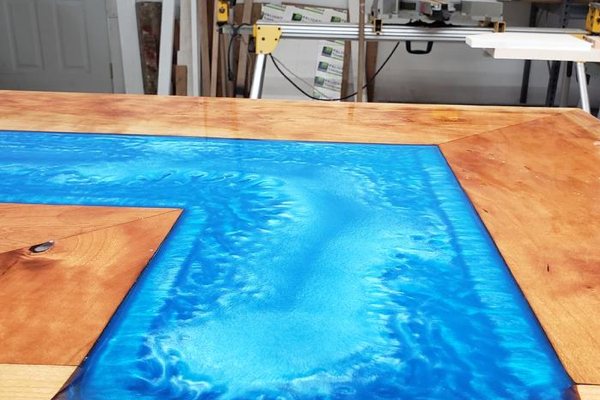

One common way to use both of these epoxies together is to apply a thick coating of deep pour, such as in the creation of a river vein for an epoxy river table, then apply a topcoating of table top epoxy a few hours later.

By using them together, you get the convenience and time-saving benefits of a deep pour layer alongside the thinner but incredibly resilient finishing strength of table top epoxy.

Additional Resources

Here are some additional resources you may find useful:

- Do you need to sand between coats of epoxy? - Sometimes sanding is necessary; sometimes it isn't. Learn more here.

- How thick should bar top epoxy be? - Knowing how thick to make your finish can help you plan out your project.

- How does water affect epoxy? Is it waterproof? - Discover how water and moisture affect epoxy, both before and after it finishes curing.

Have Questions? Want Advice? We're Here to Help!

If you have any questions about epoxy resin, or if you'd like assistance in planning an epoxy project, please reach out to us at UltraClear Epoxy—our epoxy experts are ready to assist!

You can contact us via phone or email here. During business hours, you can also text chat online with one of our resin specialists by clicking the Help button at the bottom of your screen.

In our online store, you'll find a variety of useful tools and supplies, ideal for resin projects, plus our award-winning UltraClear Bar & Table Top Epoxy and our UltraClear Deep Pour Epoxy.

UltraClear Epoxy—Trusted by over 1 Million+ Happy Customers